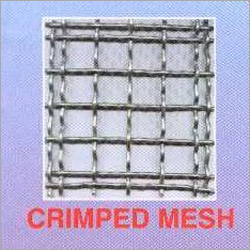

Crimped Wire Mesh

40 INR/Piece

Product Details:

- Wire Gauge 10 SWG to 25 SWG

- Aperture 6 mm to 100 mm

- Length Customized, up to 30 meters

- Hole Shape Square and Rectangular

- Surface Treatment Galvanized, PVC Coated, Uncoated

- Product Type Crimped Wire Mesh

- Mesh Type Woven Mesh

- Click to View more

X

Crimped Wire Mesh Price And Quantity

- 100 Square Foot

- 40 INR/Piece

Crimped Wire Mesh Product Specifications

- Customized, Standard rolls and cut sizes

- 6 mm to 100 mm

- 0.5 mm to 6 mm

- Stainless Steel, Mild Steel, Galvanized Iron, Brass

- Crimped

- 10 SWG to 25 SWG

- Galvanized, PVC Coated, Uncoated

- Customized, up to 30 meters

- Varies as per size and material, typically from 2 kg to 100 kg per roll

- Silver, Black, Green (as per coating)

- Square and Rectangular

- Crimped Wire Mesh

- Fencing, Sieving, Industrial Filtration, Mining, Construction, Decoration

- Woven Mesh

- 304, 316, 316L (Stainless Steel), others on request

Crimped Wire Mesh Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

We are counted among the most distinguished organizations that are engaged in manufacturing and exporting of Crimped Wire Mesh. Our team of skilled and trained professionals have the ability to test these products as per the industrial standards. These are manufactured using stainless steel sourced from the trusted vendors of the society. The offered range of wire mesh is commonly used for screening operations and also in windows, verandas & counter shelves. Crimped Wire Mesh are available in the market at competitive prices to our patrons.

Features of Crimped Wire Mesh

- Available in different materials and weaving patterns

- Highly suitable for the most demanding industries like construction, mining, cement, petrochemical and food processing

- These have got excellent consistency

- The mesh screens are bended by molding and hence posses high strength

- Adaptable to low as well as high temperatures

- Highly resistant to acids and chemicals

- Can bear heavy loads easily

Specifications:

- Material: high carbon steel / stainless steel

- Wire Diameter: 1-12 mm

Pre-crimped Weave Styles of Wire Cloth Weaving

The Pre-Crimped wire mesh we offer is made of wire dia with 6G to 18G. It is used for several applications like in the manufacturing of windows, counter shelves, veranda partitions and many more. Besides this, it has several industrial uses in coal mines for heavy screening & sieving.

In the pre-crimping process the wire is first crimped and formed in precision machines. The rotary dies used in their making help in the proper spacing of the wires and ensures that the wires lock strongly together at all the intersections. Then these pre-crimped wires are assembled together in custom designed screen assembly looms.

The extra crimps between the intersections of the wire mesh gives rigid and tight weave locking for light wires as well.

Pre-crimped wire cloth has accurate openings and thus, it is used mostly for vibrating screens and wherever sizing is critical.

- Accurate & Consistent

- Square & Rectangular

- Opening from 3 / 8" to 4" with wire Rods upto 20mm

- Made of stainless steel, high carbon high tensile, spring steel etc.

Customizable Mesh Dimensions and Styles

Choose between standard rolls or tailored cut sizes to perfectly suit your projects requirements. With multiple mesh styles such as crimped and woven mesh, and hole shapes including square and rectangular, our wire mesh adapts effortlessly to unique applications in both industrial and decorative fields.

Durable Materials and Finishes

Made from high-quality alloys, including stainless steel 304, 316, 316L, and other metals like mild steel and brass. The mesh can be supplied with galvanized, PVC-coated, or uncoated surfaces, ensuring longevity and resilience in harsh environments. Color optionssilver, black, and greenprovide both functional and aesthetic value.

FAQs of Crimped Wire Mesh:

Q: How is the crimped wire mesh manufactured to ensure durability and flexibility?

A: The mesh is produced by weaving or crimping wires, using strong materials such as stainless steel, brass, or galvanized iron. Crimping adds structural integrity, while surface treatments like galvanizing or PVC coating protect against corrosion, ensuring lasting performance in demanding applications.Q: What customization options are available for wire mesh size, shape, and color?

A: Clients can select wire gauges from 10 SWG to 25 SWG, aperture sizes from 6 mm to 100 mm, wire diameters between 0.5 mm and 6 mm, and mesh lengths up to 30 meters. Options include square and rectangular holes, various mesh styles, and multiple finishes available in silver, black, or green hues.Q: When should I choose a galvanized or PVC-coated crimped wire mesh over an uncoated option?

A: Coated mesh varieties are advisable for outdoor or industrial settings exposed to moisture, chemicals, or abrasion. Galvanizing offers enhanced rust protection, while PVC coating adds a protective layer and color. Uncoated mesh suits dry, indoor, or decorative uses where corrosion risk is minimal.Q: Where is crimped wire mesh typically installed and used?

A: It is widely employed in fencing for security or demarcation, sieving for particle separation, industrial filtration, mining operations, construction reinforcement, and both indoor and outdoor decorative projects. Its flexibility in form and finish makes it suitable across commercial, industrial, and residential settings.Q: What processes are involved in selecting and ordering a custom wire mesh?

A: To order, determine specifications like material type, wire gauge, mesh style, surface treatment, color preference, and dimensions. Consult with the supplier or manufacturer for application guidance and provide sizing details for standard rolls or custom cut sizes. Orders are manufactured and dispatched as per requirements.Q: How does using crimped wire mesh benefit industrial operations or construction projects?

A: Crimped wire mesh delivers reliable strength, ventilation, and filtration, adapts to high-stress environments, and is easy to install and maintain. Its versatility for sieving, fencing, filtration, and reinforcement streamlines industrial processes while enhancing safety and operational efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'SS Wire Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS