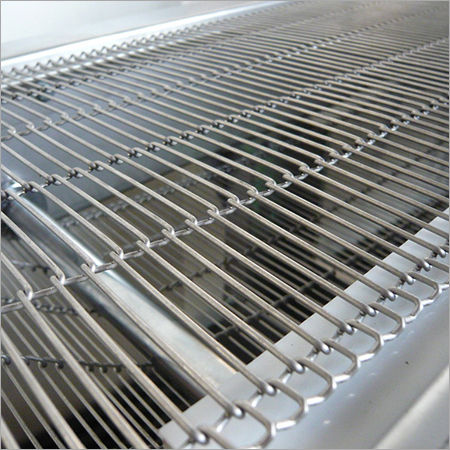

Enrober Wire Belt

40 INR/Piece

Product Details:

- Features Easy to clean, Lightweight, Durable

- Thickness Standard (customizable)

- Belt Type Enrober Belt

- Surface Finish Polished

- Material Stainless Steel

- Type Wire Mesh Conveyor Belt

- Structure Wire Mesh

- Click to View more

X

Enrober Wire Belt Price And Quantity

- 100 Square Foot

- 40 INR/Piece

Enrober Wire Belt Product Specifications

- Enrober Belt

- Stainless Steel

- Food processing, chocolate coating, baking, cooling, and conveying delicate products

- Corrosion Resistant, Heat Resistant

- Wire Mesh

- Yes

- Easy to clean, Lightweight, Durable

- Customizable

- Wire Mesh Conveyor Belt

- Standard; Customizable on request

- Polished

- Optional

- Standard (customizable)

Enrober Wire Belt Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

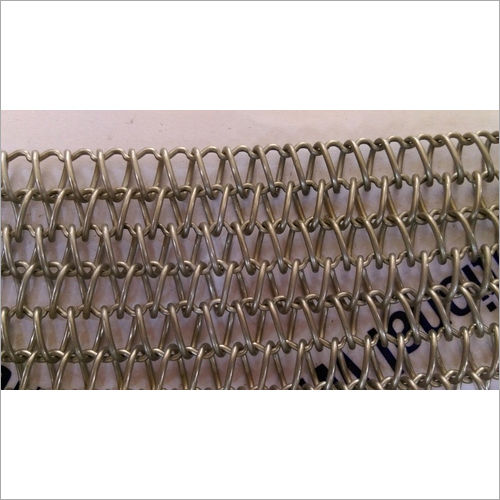

Enrober Wire Belt is a special type of conveyor belt that is used for food grade to avoid any and every kind of contamination in food products. It is made up of stainless steel in different sizes, widths, thicknesses and diameters and can be developed for both curvy as well as straight conveyors. Enrober wire belt can be outfitted with little cams or specially developed internal wire to carry a large variety of products and is usually controlled by toothed sprockets that are made of both stainless steel and plastic. These sprockets are designed to fit the belt and can be customized as per the desires of the customers.

Optimized for Food Processing Efficiency

Engineered to withstand high temperatures and rigorous processing conditions, the Enrober Wire Belt ensures smooth handling of food products like chocolates, pastries, and baked goods. A polished surface minimizes sticking while the lightweight yet durable construction streamlines cleaning operations and product changeovers, supporting consistent production output.

Versatility for Custom Manufacturing

With customizable pitch, mesh size, width, and length, the Enrober Wire Belt meets diverse conveyor requirements. Whether you need to process small candies or large bakery items, tailored configurations and optional roller conveyor integration expand its utility across various food processing industries.

FAQs of Enrober Wire Belt:

Q: How does the Enrober Wire Belt benefit food processing lines?

A: The Enrober Wire Belt is designed for minimal maintenance and easy cleaning, which helps maintain high hygiene standards. Its corrosion and heat-resistant stainless steel construction ensures durability and reliable performance in demanding food processing environments such as chocolate enrobing and baking.Q: What customization options are available for this wire belt?

A: Customers can specify belt width (from 300 mm to 2000 mm), pitch (typically between 6 mm and 25 mm), mesh opening size, belt length, and thickness. Edges can be either welded or looped, and both standard and custom options are available to match unique process needs.Q: Where can the Enrober Wire Belt be used?

A: This belt is ideal for food processing facilities, bakeries, chocolate coating lines, cooling tunnels, and any application requiring gentle, hygienic conveying of delicate food products. Its versatility extends to any production environment that values efficiency and food safety compliance.Q: What is the process for installing and maintaining the Enrober Wire Belt?

A: Installation is straightforward due to its lightweight structure and customizable manufacturing. The belt requires minimal maintenance and can be easily removed for cleaning, ensuring long operational life and decreased downtime.Q: When should you choose a welded edge versus a looped edge construction?

A: Welded edges offer enhanced durability and are suited to applications with higher loads or stricter hygiene requirements, while looped edges provide flexibility and may be preferred where belt articulation is needed or sharp radius conveyors are used.Q: How does the Enrober Wire Belt ensure food safety compliance?

A: Manufactured from food-grade stainless steel, the belt complies with FDA and EU food safety standards. Its polished surface and ease of cleaning help minimize contamination risks, supporting the stringent requirements of food manufacturing environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Wire Mesh Conveyor Belts' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS