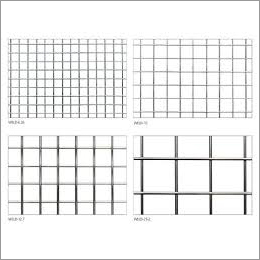

Welded Square Wire Mesh

40 INR/Piece

Product Details:

- Length 15 m, 25 m, 30 m (as per requirement)

- Aperture 12.5 mm, 25 mm, 50 mm (custom sizes available)

- Surface Treatment Galvanized, PVC coated

- Hole Shape Square

- Wire Gauge 14, 16, 18, 20, 22 SWG (customizable)

- Product Type Welded Square Wire Mesh

- Mesh Type Square Mesh

- Click to View more

X

Welded Square Wire Mesh Price And Quantity

- 100 Square Foot

- 40 INR/Piece

Welded Square Wire Mesh Product Specifications

- Available in Low Carbon Steel, Stainless Steel (AISI 304/316)

- 0.6 m 2.5 m width, custom lengths

- Welded Mesh

- Mild Steel, Stainless Steel

- 1.2 mm 2.8 mm

- Varies as per size and gauge

- Fencing, Construction, Industrial Use, Animal Cages

- Welded Square Wire Mesh

- 12.5 mm, 25 mm, 50 mm (custom sizes available)

- Galvanized, PVC coated

- 15 m, 25 m, 30 m (as per requirement)

- Square

- 14, 16, 18, 20, 22 SWG (customizable)

- Silver, Green (for PVC coated)

- Square Mesh

Welded Square Wire Mesh Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

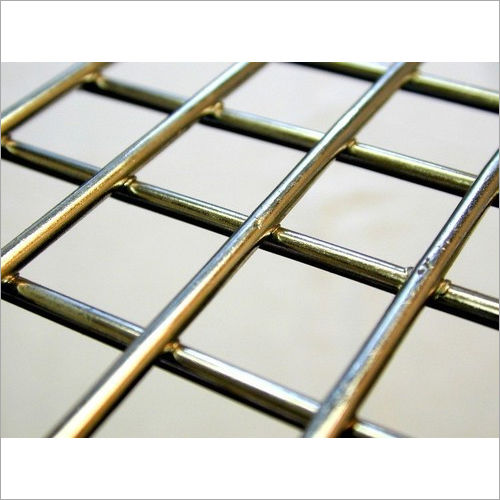

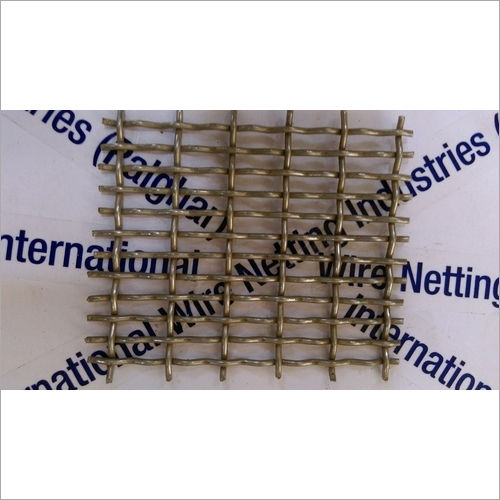

We are highly trusted among clients for manufacturing and exporting light weight Welded Square Wire Mesh. With a rigid design, this wire mesh is very convenient to handle. The wire mesh is manufactured using best quality materials and properly coated for long term protection against corrosion. Completely abrasion and wear free, the Welded Square Wire Mesh can easily withstand extreme temperature conditions. We offer this wire mesh to clients in different opening sizes and shapes to fulfill their wide applications requirements.

Features:

- Weather resistance

- Accurate dimensions

- Long lifespan

Product details

| Wire Diameter | 6.0, 8.0, 10.0 mm |

| Hole Shape | Round |

| Type | Perforated |

| Surface Finishing | Galvanised |

| Material | Low-Carbon Iron Wire |

| Usage/Application | Industrial |

Exceptional Customization and Durability

Our welded square wire mesh offers extensive customization in dimensions, aperture sizes, and finishes, catering to specific project needs. With a tensile strength of 350550 N/mm, it withstands demanding use whether indoors or outdoors. Clients can choose from plain or reinforced edges and various protective coatings for enhanced longevity.

Superior Corrosion Resistance and Standards Compliance

Engineered for durability, the mesh is available in galvanized and PVC-coated options, protecting against weathering and corrosion. Meeting ASTM and IS standards, as well as project-specific requirements, it is suitable for rigorous applications across construction, fencing, and industrial sectors.

Versatile Applications Across Industries

Welded square wire mesh serves numerous industries, from construction to agriculture and animal husbandry. Its spot-welded structure provides reliability for fencing, partitioning, machinery safety, and animal enclosures. The diverse mesh styles and material options make it adaptable for both heavy-duty and light-duty applications.

FAQs of Welded Square Wire Mesh:

Q: How is the welded square wire mesh manufactured?

A: Welded square wire mesh is produced by spot welding wires together at their intersections. This resistant welding ensures firm joints and consistent mesh openings, enhancing structural integrity.Q: What customization options are available for roll length and aperture size?

A: Standard roll lengths are 25 meters, but custom lengths such as 15 m or 30 m can be provided. Similarly, apertures can be set at 12.5 mm, 25 mm, or 50 mm, with other custom sizes available based on specific requirements.Q: When should I choose galvanized versus PVC-coated mesh?

A: Galvanized mesh offers excellent corrosion resistance for most applications. For environments with high moisture or chemical exposure, PVC-coated mesh provides an additional protective layer and a choice of colors like green or silver.Q: Where can welded square wire mesh be used?

A: This mesh is widely used in fencing, construction, industrial safety barriers, and animal cages. Its corrosion resistance makes it suitable for both indoor and outdoor settings, adapting well to diverse climates.Q: What benefits does spot welding provide over other joining methods?

A: Spot welding at each intersection creates a rigid and stable mesh structure that resists deformation, ensuring lasting performance even under heavy loads or frequent handling.Q: How do I select the appropriate wire gauge and material for my application?

A: Your choice depends on the intended useheavier gauges and stainless steel are suited for high-strength or corrosive environments, while lighter gauges and mild steel suffice for lighter-duty or temporary installations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'SS Wire Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS