Double Crimped Wire Mesh

40 INR/Piece

Product Details:

- Surface Treatment Galvanized or PVC Coated

- Hole Shape Square

- Wire Gauge 2 SWG to 14 SWG

- Length 15 m, 30 m, or as required

- Aperture 6 mm to 100 mm

- Product Type Double Crimped Wire Mesh

- Mesh Type Woven Mesh

- Click to View more

X

Double Crimped Wire Mesh Price And Quantity

- 100 Square Foot

- 40 INR/Piece

Double Crimped Wire Mesh Product Specifications

- 1.6 mm to 6 mm

- Crimped

- Galvanized or PVC Coated

- Available in various grades of SS and MS

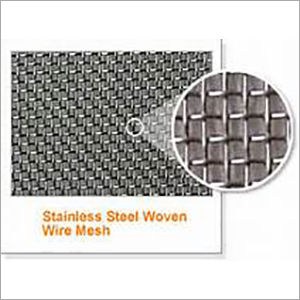

- Woven Mesh

- As per specification and size

- Square

- Stainless Steel, Mild Steel, GI Wire

- 2 SWG to 14 SWG

- 15 m, 30 m, or as required

- Fencing, Sieving, Partitioning, Mining, Construction

- Double Crimped Wire Mesh

- Custom size as per order

- 6 mm to 100 mm

- Silver, Green, Black, or as per requirement

Double Crimped Wire Mesh Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

We have been successfully operating in the industry by offering our utmost quality and superlative Double Crimped Wire Mesh. Tested as per the set standard of quality, these products are manufactured and exported using topmost quality raw material. These wire mesh find their applications in sugar mills, paper, coal and mining industries. The offered range of double crimped metal wire mesh is available in different sizes and specifications as demanded by our patrons. Our customers can avail these products at reasonable prices.

Features of Double Crimped Wire Mesh

- These are highly appreciated for their corrosion resistance

- Best known among clients for their excellent resistance against abrasions

- The wire mesh are high in strength

- Manufactured to bear heavy loads

- Stringently tested for their finishing and durability

- Widely applicable in cement, paper, sugar, coal and mining industry

- These are light in weight and easy to handle

Product details

| Material | Stainless Steel, Spring Steel, High Carbon High Tensile, G.I. & M.S. Wire |

| Type | Crimped |

| Weave Type | Twill |

| Hole Shape | Diamond |

| Usage | Industrial |

| Wire diameter | 6G to 18G |

Wide Range of Applications

Double Crimped Wire Mesh is engineered for diverse industrial and commercial uses. Its robust structure makes it suitable for fencing, sieving, partitioning, construction sites, and mining operations. Depending on specific requirements, mesh specifications can be tailored for optimal performance.

Customizable Features and Grades

Customers can select from multiple wire gauges, aperture sizes, surface treatments, and colors. The mesh is available in stainless steel, mild steel, and GI wire materials, along with various alloy grades. Lengths and sizes are fully customizable to suit particular applications or project needs.

Durable Construction and Coating

To ensure longevity and resistance to wear, Double Crimped Wire Mesh is available with galvanized or PVC coatings. These treatments enhance corrosion resistance, making the mesh suitable for both indoor and outdoor applications. The woven crimped style maintains mesh rigidity and uniform aperture size.

FAQs of Double Crimped Wire Mesh:

Q: How is Double Crimped Wire Mesh installed for fencing or partitioning?

A: Double Crimped Wire Mesh can be secured to frames, posts, or existing structures using clamps, wires, or fasteners. Installation methods vary according to the mesh size and application, but professional fitment ensures stability and longevity.Q: What materials are used to manufacture Double Crimped Wire Mesh?

A: This mesh is crafted from high-quality stainless steel, mild steel, or galvanized iron (GI) wire. Material choice depends on usage requirements, environmental factors, and desired durability.Q: When should I opt for galvanized or PVC coated surface treatment?

A: Galvanized and PVC coating should be chosen when corrosion resistance is a priority, such as in outdoor settings, humid environments, or areas exposed to chemicals. These coatings enhance the lifespan and performance of the mesh.Q: Where can Double Crimped Wire Mesh be applied?

A: The mesh is widely used for fencing, sieving, partitioning in industrial and commercial settings, mining operations, and construction sites. Its flexible design allows it to be incorporated wherever strong and durable screening or separation is required.Q: What is the manufacturing process for Double Crimped Wire Mesh?

A: The process involves weaving wires in a crimped pattern to create uniform apertures. Wires are double crimped for increased rigidity, and the mesh is then cut or finished based on custom dimensions and surface treatments requested by the customer.Q: How can customizing aperture and wire gauge benefit my application?

A: Customizing aperture and wire gauge allows you to control the strength, filtration capability, and transparency of the mesh. It ensures compatibility with intended usage, whether for sturdiness in fencing or precision in sieving.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'SS Wire Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free