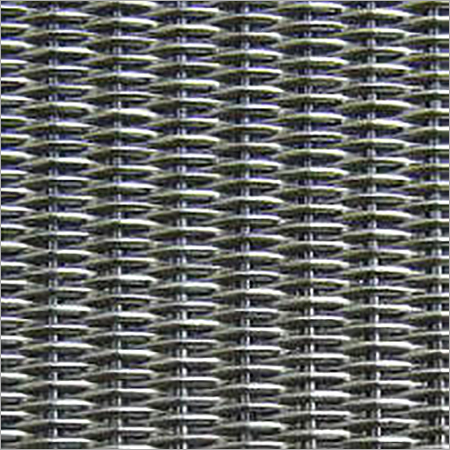

Hollander Weave Mesh

40 INR/Piece

Product Details:

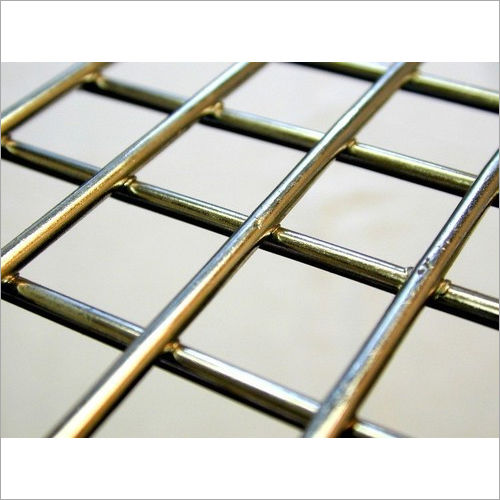

- Surface Treatment Polished, Galvanised

- Wire Gauge As per requirement, typically 8 to 32 SWG

- Aperture 0.02 mm to 2 mm

- Length 15 to 30 meters (Standard Roll)

- Hole Shape Rectangular/Oblong

- Product Type Woven Wire Mesh

- Mesh Type Fine Mesh

- Click to View more

X

Hollander Weave Mesh Price And Quantity

- 40 INR/Piece

- 100 Square Foot

Hollander Weave Mesh Product Specifications

- Rectangular/Oblong

- Stainless Steel Grades (304, 316), Brass, Bronze

- Varies as per gauge and width

- Filtration, Sieving, Industrial Screening

- 0.02 mm to 2 mm

- 0.02 mm to 2 mm

- Silver/Grey

- As per requirement, typically 8 to 32 SWG

- Polished, Galvanised

- Woven Wire Mesh

- Widths: 15 cm to 200 cm

- Stainless Steel (304, 316), Brass, Phosphor Bronze

- Fine Mesh

- Hollander (Dutch) Weave

- 15 to 30 meters (Standard Roll)

Hollander Weave Mesh Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

Hollander Weave Mesh is an evenly weaved structure, made using limited number of warp wires of comparatively larger diameter than weft wire and is interlocked with optimum number of weft wires. It is exquisitely designed as strong and firm cloth to suit various high pressure filtration applications in commercial as well as non-commercial areas. During the weaving process, both the wires are driven closer to provide more compact and dense media. Resistance to corrosion & abrasion, sturdiness and longer serving life is a result of high grade steel that we use while developing the provided Hollander metal weave mesh.

Exceptional Filtration Precision

Hollander Weave Mesh excels in applications requiring high-precision filtration thanks to its unique Dutch weave design. With mesh counts reaching up to 500 and apertures as narrow as 0.02 mm, it effectively screens and separates even the finest particles, making it ideal for critical industrial processes.

Robust Material and Temperature Versatility

Crafted from premium alloys like stainless steel (304, 316), brass, and phosphor bronze, this mesh offers remarkable corrosion resistance and can withstand temperatures up to 800C. Its durability makes it suitable for challenging environments in the chemical, petrochemical, and food sectors.

Customizable to Industry Demands

Offered in various lengths, widths, and wire gauges, Hollander Weave Mesh accommodates specific client requirements. Manufacturers provide a range of edge types and surface finishes, ensuring seamless integration into existing filtration, screening, and sieving systems across multiple industries.

FAQs of Hollander Weave Mesh:

Q: How is Hollander Weave Mesh typically used in industrial applications?

A: This mesh is commonly employed for filtration, sieving, and industrial screening processes, particularly in chemical, pharmaceutical, food, and petrochemical industries due to its fine filtration capability and robust construction.Q: What benefits does Dutch (Hollander) Weave provide over standard mesh designs?

A: Dutch weave offers a finer and tighter structure with reduced open area, enabling exceptionally precise filtration of minute particles while maintaining mechanical strength suitable for demanding industrial settings.Q: What are the available customization options for Hollander Weave Mesh?

A: Buyers can request custom mesh count, width, wire diameter, length, edge type (plain or selvage), and surface treatment. This ensures the mesh fits unique application requirements and processing equipment.Q: When should I consider using stainless steel grades 304 or 316 for my mesh?

A: Opt for stainless steel 304 for general corrosion resistance, while stainless steel 316 is recommended for more aggressive chemical environments or higher temperature applications up to 800C for maximum durability.Q: Where are Hollander Weave Mesh products manufactured and supplied from?

A: These meshes are largely manufactured, exported, and distributed by industry suppliers based in India, with global reach to serve varied industrial filtration needs.Q: What process is used to ensure the mesh arrives in optimal condition?

A: Each roll of mesh is securely packed in moisture-proof paper and plastic wrap, safeguarding it against humidity and external contaminants during storage and transit.Q: What is the range for the mesh count, wire gauge, and aperture available?

A: The mesh count can be specified up to 500 mesh, with wire gauges typically between 8 and 32 SWG, and apertures (hole sizes) ranging from 0.02 mm to 2 mm, providing versatility for precise application needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'SS Wire Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS