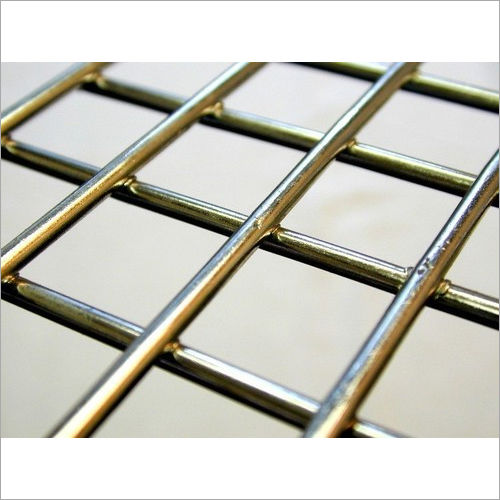

Hot Dipped Galvanized Wire Mesh

40 INR/Piece

Product Details:

- Hole Shape Square

- Surface Treatment Hot Dipped Galvanized

- Aperture 0.5 inch to 4 inch

- Wire Gauge 0.5 mm to 2.5 mm

- Length as per requirement (commonly in rolls of 15 to 30 meters)

- Product Type Wire Mesh

- Mesh Type Galvanized Iron (GI) Mesh

- Click to View more

X

Hot Dipped Galvanized Wire Mesh Price And Quantity

- 40 INR/Piece

- 100 Square Foot

Hot Dipped Galvanized Wire Mesh Product Specifications

- 0.5 inch to 4 inch

- as per requirement (commonly in rolls of 15 to 30 meters)

- 0.5 mm 2.5 mm

- Silver

- Non-Alloy

- 0.5 mm to 2.5 mm

- Low Carbon Steel / Mild Steel

- customizable (width typically 1 m, 1.2 m, 1.5 m)

- Galvanized Iron (GI) Mesh

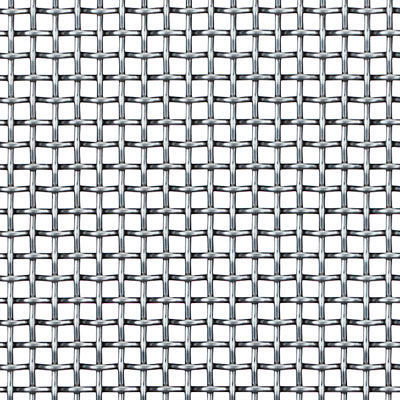

- Welded or Woven

- as per specification (depends on dimensions and gauge)

- Wire Mesh

- Fencing, Industrial, Construction, Poultry, Agriculture

- Square

- Hot Dipped Galvanized

Hot Dipped Galvanized Wire Mesh Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

Our company is best known as the prominent manufacturer and exporter of an excellent quality Hot Dipped Galvanized Wire Mesh. The wire mesh is widely used in protection systems, building construction, food, filtration and agriculture industry. We use excellent quality plain steel wires to manufacture this mesh by welding. In addition, this product is also surface treated for a perfect finishing. We offer this wire mesh to clients at highly competitive price.

Features of Hot Dipped Galvanized Wire Mesh

- Firm structure

- Flat and uniform surface

- Good corrosion resistance

Superior Corrosion Resistance

With a high zinc coating (40200 gsm), this galvanized wire mesh provides long-lasting protection against rust and corrosion, making it highly suitable for outdoor or harsh environments. The galvanization process ensures reliable performance, extending the meshs lifespan even when exposed to moisture, chemicals, or temperature extremes.

Flexible Applications and Customization

The wire mesh can be tailored in terms of aperture size (0.5 inch to 4 inch), width (1 m, 1.2 m, 1.5 m), and wire gauge (0.52.5 mm), meeting diverse needs in fencing, agriculture, construction, and animal enclosures. Its adaptability makes it suitable for soil reinforcement, window guards, protective cages, and more.

Reliable Strength and Safety

Manufactured with a tensile strength between 350550 N/mm and available in welded or woven forms, the mesh offers robust structural integrity and secure barrier solutions. Whether used for industrial reinforcement or livestock protection, it stands up to physical impact and maintains condition over time.

FAQs of Hot Dipped Galvanized Wire Mesh:

Q: How is the hot dipped galvanized wire mesh manufactured?

A: The mesh is produced by weaving or welding low carbon or mild steel wires, followed by hot dipping them in molten zinc. This process ensures a uniform, strong zinc coating (40200 gsm) over the surface, significantly enhancing its corrosion resistance.Q: What are the main benefits of using hot dipped galvanized wire mesh?

A: Its primary advantages include very high corrosion resistance, customizable dimensions, superior tensile strength, and long service life. The mesh withstands demanding environments and is suitable for multiple applications such as fencing, animal cages, and construction reinforcement.Q: When should I choose twisted edged mesh over plain edge types?

A: Twisted edge mesh offers extra strength at borders and is generally preferred for applications demanding higher security or minimizing edge fraying. Plain edges are more common for standard projects like window guards or garden protection where added border strength is not critical.Q: Where can hot dipped galvanized wire mesh be used effectively?

A: This mesh is suitable for various environments including agricultural fields, residential fencing, industrial construction sites, and animal enclosures. Its strong corrosion resistance makes it ideal for both indoor and outdoor use in regions with high moisture or chemical exposure.Q: What gauges and apertures are available for customization?

A: Wire gauges range from 0.5 mm to 2.5 mm, and apertures vary from 0.5 inch to 4 inch. Both parameters, along with width and length, can be tailored as per project requirements, ensuring an optimal fit for specific applications.Q: How does the mesh perform under high temperatures?

A: With a temperature resistance up to 320C, the mesh maintains its structural integrity and protective zinc layer in most standard and moderately high heat environments, making it reliable for industrial uses.Q: What is the process for ordering and what is the minimum quantity?

A: Orders can be placed through certified distributors, exporters, manufacturers, or suppliers in India. The minimum order quantity is 500 square meters, and the mesh is typically supplied in rolls (1530 meters per roll) or bundles, depending on customer requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'SS Wire Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS