Vibrating Screen Mesh

Product Details:

- Hole Shape Square, Rectangular

- Aperture 3 mm to 100 mm

- Length Up to 30 Meter

- Surface Treatment Galvanized / Non-Galvanized

- Wire Gauge 2mm to 12mm

- Product Type Vibrating Screen Mesh

- Mesh Type Heavy Duty

- Click to View more

Vibrating Screen Mesh Price And Quantity

- 100 Square Foot

- 40 INR/Piece

Vibrating Screen Mesh Product Specifications

- Available in Standard & High Carbon

- Woven / Welded

- Heavy Duty

- Silver

- 2 - 12 mm

- 2mm to 12mm

- Mining, Quarry, Coal, Cement, Construction, Screening

- Spring Steel, Stainless Steel, Mild Steel

- Vibrating Screen Mesh

- Customized

- Galvanized / Non-Galvanized

- Square, Rectangular

- As per size

- Up to 30 Meter

- 3 mm to 100 mm

Vibrating Screen Mesh Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

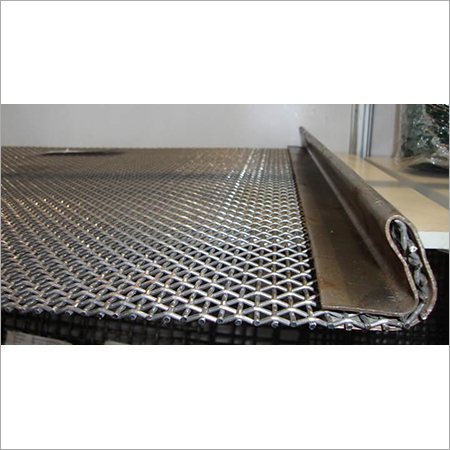

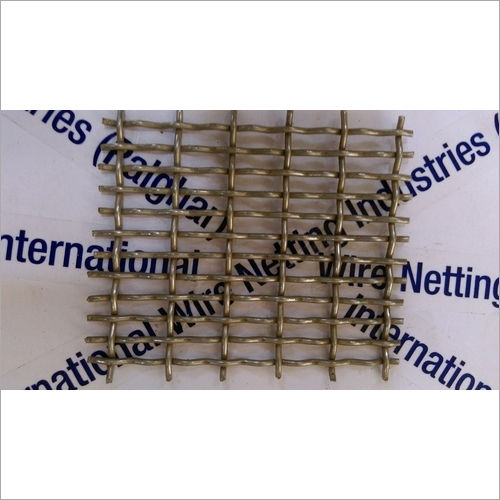

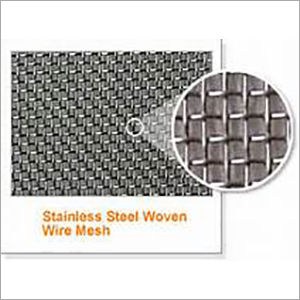

Vibrating Screen Mesh is woven from pre-crimped manganese steel or stainless steel wire that offers good strength and stable structure. Also, to suit the requirements of the customer it is custom made in different materials, sizes and ranges. This type of mesh finds huge applicability in cement, power plants, paper & pulp, iron ore & steel and mining industry for doing various tasks such as shifting, grading, separating, scalping, sizing and screening. It possess excellent ability to work under extreme adverse conditions and shows high resistance to corrosion, chemicals and abrasion.

Product details

| No of Mesh | 100 |

| Material | Stainless Steel |

| Surface Finishing | Galvanized |

| Hole Shape | Rectangular |

| Application | Chemical Industry,Building Material,Coal Mine,Mineral Separation,Abrasive Industry |

| Material Grade | 304 or 316 |

Versatile Mesh Configurations for Industrial Applications

Our vibrating screen meshes are offered in panel, modular, or roll formats, ensuring the perfect fit for any installation scenario. Choose from square, rectangular, and custom aperture shapes, with the added benefit of woven, welded, or heavy-duty styles. These configurations make the mesh adaptable for a wide range of industries, including mining, quarry, coal, cement, and construction.

Durability That Withstands Harsh Conditions

Built from premium spring steel, stainless steel, or mild steel, and available in standard and high carbon alloys, our screen meshes provide exceptional tensile strength and corrosion resistance. Operating at temperatures up to 450C, these meshes are designed to endure the demanding requirements of continuous industrial usage, offering a long service life and minimal maintenance.

Expert Edge Preparation and Protective Packaging

Select from hooked, plain, or reinforced edges, tailored to your vibrating screens requirements for seamless installation and robust performance. Meshes are meticulously wrapped in HDPE and gunny bags to guarantee safe delivery, whether supplied as rolls, cuts, or custom-dimensioned panels.

FAQs of Vibrating Screen Mesh:

Q: How is the edge preparation of vibrating screen mesh customized for specific applications?

A: Edge preparationincluding hooked, plain, and reinforced typesis chosen based on your screen design and operational needs. Hooked edges are ideal for secure attachment to vibrating screens, while plain and reinforced edges provide flexibility and added strength for demanding tasks.Q: What materials are available for the vibrating screen mesh, and how do they benefit industrial use?

A: The mesh is manufactured from spring steel, stainless steel, and mild steel, with options for standard or high carbon alloys. These materials ensure high tensile strength and excellent corrosion resistance, making the mesh suitable for harsh environments and extending its operational life.Q: When should a woven or welded mesh style be selected?

A: Woven mesh is best for applications needing flexibility and fine apertures, such as precise sifting and grading. Welded mesh, on the other hand, is ideal for heavy-duty screening tasks where greater rigidity and durability are required.Q: Where can vibrating screen mesh with edge preparation be installed?

A: These meshes are installed in mining, quarrying, coal processing, cement manufacturing, and various construction screening operations. They are designed for compatibility with different installation types, such as panels, modular systems, or rolls, adapting effortlessly to site-specific requirements.Q: How is the vibrating screen mesh supplied and protected during shipment?

A: Meshes are delivered in rolls, specific cuts, or customized panels, securely wrapped in durable HDPE and gunny bags. This robust packaging minimizes risk of damage during handling and transport, ensuring the integrity and quality of the mesh upon arrival.Q: What is the typical process of selecting the right mesh specifications for my application?

A: Start by evaluating your required aperture size (3 mm to 100 mm), wire diameter (2 mm to 12 mm), material, and mesh style (woven/welded/heavy-duty). Consider the operating temperature and corrosive properties. Our team assists you in customizing dimensions, edge style, and treatment to match your specific industrial needs.Q: What operational benefits does high open area provide in vibrating screen mesh?

A: An open area of up to 60% enhances efficiency by allowing more material to pass through quickly, which boosts screening capacity and throughput. This is particularly valuable in mining and grading operations where processing speed and volume are critical.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'SS Wire Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free