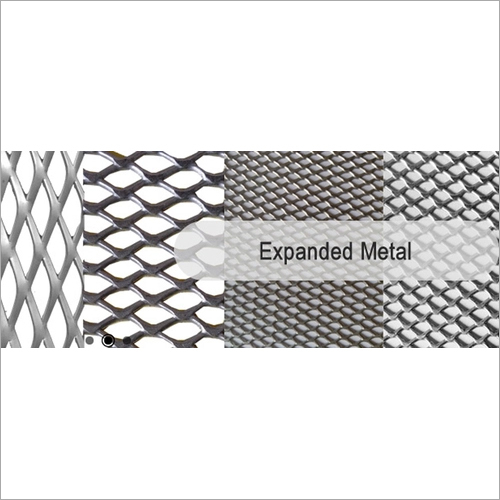

Expanded Metal Mesh

Product Details:

- Surface Treatment Galvanized / Powder Coated / Mill Finish

- Length Standard up to 8 ft, custom available

- Hole Shape Diamond

- Aperture 10 mm x 25 mm (typical)

- Wire Gauge 1 mm to 6 mm

- Product Type Expanded Metal Mesh Sheet

- Mesh Type Heavy and Light Duty

- Click to View more

Expanded Metal Mesh Price And Quantity

- 100 Square Foot

- 40 INR/Piece

Expanded Metal Mesh Product Specifications

- Fencing, Grating, Security, Filtration, Walkways, Wall Cladding

- Expanded Metal Mesh Sheet

- Heavy and Light Duty

- Galvanized / Powder Coated / Mill Finish

- Diamond

- 1 mm to 6 mm

- Standard up to 8 ft, custom available

- Mild Steel, Stainless Steel, Aluminum

- Silver, other colors available on request

- As per mesh size and thickness

- 4 ft x 8 ft standard, customizable sizes

- 1 mm to 6 mm

- 10 mm x 25 mm (typical)

- Available in standard grades; MS, SS 304, SS 316, Aluminum

- Expanded

Expanded Metal Mesh Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

Across global market place, our company is highly acclaimed as the leading manufacturer and exporter of an extensive range of Expanded Metal Mesh. Manufactured in compliance with industry standards using best quality stainless steel, galvanized iron or mild steel, this mesh is also customized in different widths and gauges as per clients specific application requirements. This sheet is slit and stretched in a wide array of openings of diamond shape. Expanded Metal Wire Mesh offers free passage of light, liquid, sound and air along with a decorative look.

The Expanded Metal Mesh is also made out of solid sheet metals that are slit and stretched together to form a diamond like pattern. This pattern is can be of regular or standard size. The pattern of the metal mesh generally varies by in size and in material type. Moreover, to get a different metal shape the sheets can be flattened by passing them through a roller or roll mill.

Expanded metal mesh are also manufactured in heavy gauges and therefore, are used in for diverse application like making of flooring, ramps, walkways etc.

Product details

| Packaging Type | Roll |

| Thickness | 0.5 mm to 50 mm |

| Material | Mild Steel (M.S.),Galvanised Iron (G.I.),Stainless Steel 304,316 (S.S.) Aluminum ( AL.) |

| Technique | Hot or Cold Rolled |

| Shape | Diamond |

| Usage | Agricultural,Domestic,Industrial |

Customizable Mesh for Versatile Industrial Use

Expanded Metal Mesh is available in multiple materials, including mild steel, stainless steel, and aluminum. Its customizable dimensions, strand widths, and mesh styles cater to both heavy and light-duty needs. Designed for fencing, grating, filtration, and architectural functions, the mesh can be finished in various treatments like galvanizing or powder coating, with color options to fit specific design or environmental requirements.

Built for Performance and Durability

Benefiting from high corrosion resistance (especially in SS and aluminum), expanded metal mesh withstands challenging environments. Its fire-resistant properties are contingent on selected material, making it suitable for safety-critical applications. Precision manufacturing and adherence to ASTM or IS standards guarantee consistent quality and durability.

FAQs of Expanded Metal Mesh:

Q: How is expanded metal mesh manufactured, and what does expanded mean?

A: Expanded metal mesh is produced by simultaneously slitting and stretching a metal sheet, creating diamond-shaped or other apertures. This process enhances strength without adding excessive weight and eliminates waste compared to perforation.Q: What are the usage scenarios for this mesh with dimensions of 10 mm x 25 mm openings and customizable thickness?

A: Expanded metal mesh with these specifications is commonly used in fencing, walkways, wall cladding, industrial filtration, security screens, and grating. The variety in strand width and thickness allows adaptation to both heavy and light-duty environments.Q: What surface treatments and finishes are available to ensure corrosion resistance?

A: The mesh can be treated with galvanized or powder-coated finishes, in addition to mill finish options. Stainless steel and aluminum versions provide inherently high corrosion resistance, making them ideal for outdoor and harsh environments.Q: When should I choose flat sheet form over raised (or vice versa) for my application?

A: Flat mesh sheets offer a smoother surface, suitable for wall cladding or flooring, while raised mesh provides enhanced traction, making it ideal for walkways, ramps, and slip-resistant platforms.Q: Where can expanded metal mesh be installed, and are custom sizes possible?

A: The mesh is suitable for installation in residential, commercial, or industrial settings including fencing, security partitions, and architectural facades. Standard sheet sizes are 4 ft x 8 ft, but custom lengths and shapes can be arranged upon request.Q: What are the benefits of selecting mill edge or trimmed edge types?

A: Mill edge meshes are supplied as originally expanded, while trimmed edges provide safer, more uniform borders, preferred for applications where aesthetics or safety is essential, such as in public-facing installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'SS Wire Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free