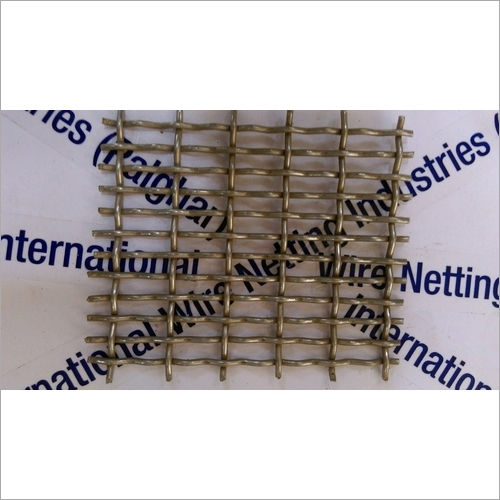

Stainless Steel Crimped Wire Mesh

40 INR/Piece

Product Details:

- Hole Shape Square or Rectangular

- Length up to 30 meters roll or as customized

- Surface Treatment Polished or Unpolished

- Wire Gauge as per requirement (commonly 2 mm to 8 mm)

- Aperture 5 mm to 100 mm

- Product Type Crimped Wire Mesh

- Mesh Type Woven Mesh

- Click to View more

X

Stainless Steel Crimped Wire Mesh Price And Quantity

- 40 INR/Piece

- 100 Square Foot

Stainless Steel Crimped Wire Mesh Product Specifications

- customized (standard width up to 2.5 m)

- Woven Mesh

- Crimped

- as per requirement (commonly 2 mm to 8 mm)

- Polished or Unpolished

- Stainless Steel (201, 202, 304, 304L, 316, 316L, 321, etc.)

- as per size and material thickness

- Square or Rectangular

- up to 30 meters roll or as customized

- Silver/Grey

- 5 mm to 100 mm

- SS201, SS304, SS316, etc.

- 1 mm - 8 mm

- Screening, Sieving, Fencing, Mining, Quarrying, Filters, Industrial, Construction

- Crimped Wire Mesh

Stainless Steel Crimped Wire Mesh Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

We are counted among the leading companies, engaged in manufacturing and exporting a wide range of Stainless Steel Crimped Wire Mesh. Our clients can get this wire mesh from us in different weaving patterns in order to meet their wide requirements. Made by using best quality stainless steel procured from reputed vendors in market, this wire mesh is high in demand for use in the most demanding industries like mining, construction, food, petrochemical and cement. In market, this Stainless Steel Crimped Wire Mesh is available at competitive price.

Features of Stainless Steel Crimped Wire Mesh

- Corrosion resistance

- Excellent consistency

- Tough design

Product details

| Material | High carbon steel / stainless steel |

| Pattern Type | Crimped |

| Roll Length | 30 meter |

| Wire Diameter | up to 20mm |

| Weave Type | Twill |

| Mesh Size | 50-100 per inch,10-50 per inch,0-10 per inch |

Superior Performance for Demanding Environments

Built from top-grade stainless steel alloys, including 201, 304, 316, and others, these crimped wire meshes excel in environments where strength and resistance are paramount. Their high tensile properties and excellent corrosion resistance ensure reliable operation in mining, quarrying, industrial filtration, and harsh outdoor conditions.

Customizable to Your Specific Needs

With a wide range of weaves, apertures (5100 mm), wire diameters (18 mm), and finishes, these meshes can be tailored to fit unique requirements. Offered in rolls up to 30 meters or in panels, and with width options up to 2.5 meters, they provide flexible solutions across various applications.

FAQs of Stainless Steel Crimped Wire Mesh:

Q: How is stainless steel crimped wire mesh manufactured and what weave types are available?

A: Stainless steel crimped wire mesh is made by weaving wires into specific patterns such as double crimp, single crimp, and lock crimp. This process enhances stability and structural integrity, making it suitable for heavy-duty and precision screening tasks.Q: What are the main benefits of using stainless steel crimped wire mesh in industrial applications?

A: This mesh offers high tensile strength, outstanding corrosion resistance, and the ability to withstand operational temperatures up to 800C (depending on the alloy). It delivers dependable performance in challenging environments such as mining, construction, and industrial filtration.Q: When should I choose welded or plain edge types for my wire mesh requirements?

A: Welded edges are recommended when maximum stability and load-bearing capabilities are needed, while plain edges are suitable for lighter duty or flexible installations. The choice depends on your applications mechanical and durability requirements.Q: Where are stainless steel crimped wire meshes commonly installed?

A: These meshes are versatile and widely employed in screening, sieving, fencing, mining, quarrying, industrial filters, and construction sites. Their adaptability to different applications makes them a staple in both indoor and outdoor settings.Q: What customization options are offered for dimensions and surface finish?

A: You can specify mesh dimensions, aperture size (5 mm to 100 mm), wire diameter (1 mm to 8 mm), and choose from finishes such as polished or unpolished, and smooth, flat, or level surfaces. Standard widths can reach up to 2.5 meters, with lengths customizable up to 30 meters or as required.Q: How does surface treatment enhance the meshs performance and longevity?

A: Surface treatment options like polishing improve the meshs resistance to corrosion, reduce contamination, and provide a smoother finish, which is especially valuable in hygienic or visually demanding applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'SS Wire Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS