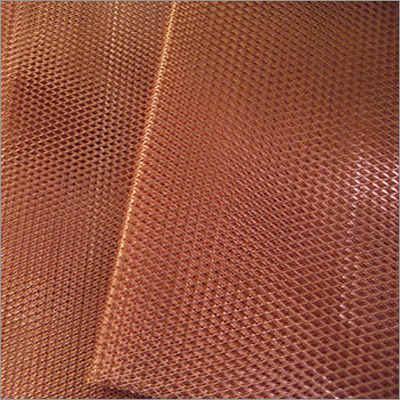

Twill Cutting-Edge Copper Wire Mesh

Product Details:

- Surface Treatment Polished

- Aperture 0.2 mm to 5 mm

- Wire Gauge 10-100 SWG

- Hole Shape Square

- Length 15-30 Meter

- Product Type Wire Mesh

- Mesh Type Woven Mesh

- Click to View more

Twill Cutting-Edge Copper Wire Mesh Price And Quantity

- 5000 , , Square Foot

- 60 INR/Square Foot

- 60.00 - 600.00 INR/Square Foot

Twill Cutting-Edge Copper Wire Mesh Product Specifications

- Woven Mesh

- Width: 1-2 Meter, Length: Customizable

- Polished

- Filtration, EMI Shielding, Insect Screening, Decoration

- Copper

- Wire Mesh

- 0.2 mm to 5 mm

- Copper

- 10-100 SWG

- 0.05 mm - 2 mm

- Pure Copper (99.9%)

- As per size & gauge

- Twill Weave

- 15-30 Meter

- Square

Twill Cutting-Edge Copper Wire Mesh Trade Information

- 20000 , , Square Foot Per Week

- 4 Week

Product Description

Twill Cutting Edge Copper Wire Mesh offered by our International Wirenetting Industries, is made using optimum quality copper materials. Our provided wire mesh is a perfect product for cable mesh applications. This wire mesh is mainly preferred for its features like nonmagnetic, electrical conductivity, and resistance to rust and sparking. Twill Cutting Edge Copper Wire Mesh is very effective and safe to use. This wire mesh is very simple to mount and easy to operate. Besides, this wire mesh can be made use of to fit different style configurations.

Product detail of Twill Cutting-Edge Copper Wire Mesh

| Mesh Size | 50-100,0-10,10-50 |

| Hole Shape | Round |

| Weave Type | Twill |

| Surface Finish Coating | Black Polyester,Black Powder,PTFE |

| Technique | Cutting-Edge |

| Material | Copper |

| Usage/Application | Industrial |

Outstanding Durability and Precision

Crafted from high-purity copper, this mesh exhibits excellent temperature and corrosion resistance. The twill weave ensures precise uniformity and strength, making it suitable for demanding applications in industries such as electronics, architecture, and manufacturing.

Versatile Applications Across Industries

Highly adaptable, our copper wire mesh serves a range of functions- from advanced filtration and reliable EMI shielding to decorative installations and insect screening. Available in various sizes, gauges, and mesh styles, clients can choose the perfect configuration for their specific requirements.

FAQ's of Twill Cutting-Edge Copper Wire Mesh:

Q: How is the Twill Cutting-Edge Copper Wire Mesh typically used?

A: This mesh is utilized in specialized applications such as industrial filtration, EMI shielding for electronics, insect screening, and even decorative architectural elements, owing to its durability, fine aperture range, and attractive copper finish.Q: What are the benefits of choosing a twill weave and polished finish for copper wire mesh?

A: Twill weave provides a robust, flexible structure that can withstand stress and maintain form. The polished surface not only enhances aesthetic appeal but also improves corrosion resistance, ensuring long-term, reliable performance.Q: When should I select a cutting edge versus a finished edge for my mesh?

A: A cutting edge is suitable for custom installations where you may need to trim the mesh to fit a precise dimension. Finished edges, on the other hand, help prevent fraying and are ideal when you need clean, ready-to-use mesh sections.Q: Where does the copper wire mesh perform best in terms of environmental conditions?

A: Thanks to its pure copper composition and excellent corrosion resistance, this mesh excels in environments with high humidity, chemical exposure, or temperature fluctuations-making it ideal for demanding industrial and architectural settings.Q: What is the process for selecting the right mesh count and opening size?

A: Consider your application's requirements: finer mesh counts (higher numbers) provide smaller openings suited for filtration or EMI shielding, while larger openings are ideal for ventilation or insect screening. Aperture can be customized between 0.2 mm and 5 mm based on your project's needs.Q: How is the mesh packed and supplied to customers?

A: The mesh is available in both roll and sheet forms, with lengths ranging from 15 to 30 meters and widths from 1 to 2 meters. Custom dimensions are provided to match specific needs, while careful packaging ensures it arrives in excellent condition.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free