Wire Screen Cloth

Product Details:

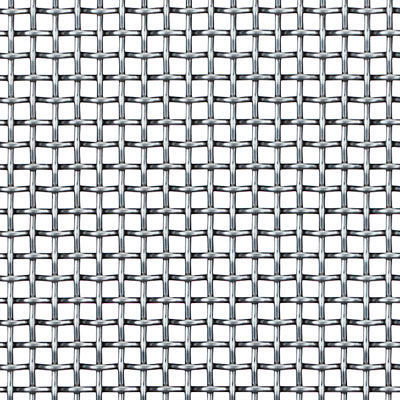

- Aperture 3 mm

- Hole Shape Square

- Surface Treatment Galvanized

- Length 3 Meter

- Wire Gauge 22 SWG

- Product Type Wire Screen Cloth

- Mesh Type Screen Mesh

- Click to View more

Wire Screen Cloth Price And Quantity

- 100 Square Foot

- 40 INR/Piece

Wire Screen Cloth Product Specifications

- Low-Carbon Steel

- Square

- 3 mm

- Galvanized

- Silver

- Sieving, Filtration, Industrial Screening, Fencing

- 3 m x 1 m

- 3 Meter

- Wire Screen Cloth

- Approx. 3.5 kg per sheet

- 22 SWG

- Woven Mesh

- 0.64 mm

- Mild Steel

- Screen Mesh

Wire Screen Cloth Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

We are offering extremely suitable for screening various materials and is available in different wire diameters, mesh sizes and apertures. To suit the demands of the customers, as per the area of applicability and usage, this type of cloth is also developed in custom made sizes. Excellent resistance to corrosion, acid, alkali, durable life, high stability, easy to maintain, simple to clean is what describes our exquisitely designed provided product. It finds suitability in various domains like chemical processing to process powders and liquids, food processing to process corns, nuts, spices, potatoes and various other agricultural products, water and waste treatment water filtration and sand & gravel- for sizing and washing of aggregates, gravel and sand.

Superior Durability and Versatility

Our wire screen cloth boasts exceptional tensile strength, making it highly suitable for tough environments like construction and mining. The moderate corrosion resistance, enhanced by a galvanized surface, protects against harsh weather and working conditions. Its versatility makes it adaptable for industrial screening, sieving, fencing, and more.

Precision Engineering for Reliable Performance

Manufactured from low-carbon mild steel and processed in plain weave with 3 mm square apertures, this mesh guarantees uniformity and efficiency. The flat edges ensure seamless installation, while the woven mesh style offers consistent filtration or screening in both rolls and sheet formats.

Convenient Sizing and Packaging

Available in 3 m x 1 m dimensions and around 3.5 kg per sheet, our wire cloth is simple to handle and transport. Choose between rolls or sheets to meet your specific requirements and benefit from easy storage and swift deployment at job sites within construction, mining, agriculture, and more.

FAQs of Wire Screen Cloth:

Q: How can the wire screen cloth be installed for fencing or screening applications?

A: The wire screen cloth with flat edges can be easily affixed to frames or structures using fasteners or clamps. Its sturdy construction allows it to be tensioned securely, whether mounted vertically for fencing or horizontally for screening and filtration tasks.Q: What are the main benefits of choosing a galvanized mild steel wire mesh for industrial use?

A: Opting for galvanized mild steel mesh combines high tensile strength with moderate resistance to corrosion. This ensures a longer service life, reduced maintenance, and suitability for demanding environments such as construction, mining, and agriculture.Q: When should I use sheets versus rolls for my application?

A: Sheets are ideal for projects requiring specific, manageable dimensions, such as fencing sections or panels for filtration. Rolls provide greater flexibility and continuity for larger surface coverage, making them suitable for custom sizing on-site or continuous screening arrangements.Q: Where can this wire mesh be applied effectively?

A: This wire mesh is commonly used in construction for sieving and filtration, mining for particle screening, agriculture for crop protection, and as fencing material in industrial areas. Its versatility is further enhanced by its durability and ease of installation.Q: What is the weaving process used in this mesh, and how does it affect performance?

A: The wire screen cloth is made using plain weave, where each wire passes alternately over and under adjacent wires, forming a square aperture. This process offers high structural integrity, precise aperture sizing, and excellent screening or filtering performance.Q: How does the wire screen cloths temperature resistance contribute to its usage?

A: With resistance up to 300C, this wire mesh is suitable for applications involving moderate heat, such as certain industrial screening and filtration processes, without risk of deformation or strength loss.Q: What advantages does high tensile strength provide for industrial and commercial applications?

A: High tensile strength ensures the wire mesh can withstand heavy loads, mechanical stress, and impacts. This is crucial for construction, mining, and agricultural uses, where reliability and consistent performance are required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'SS Wire Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free