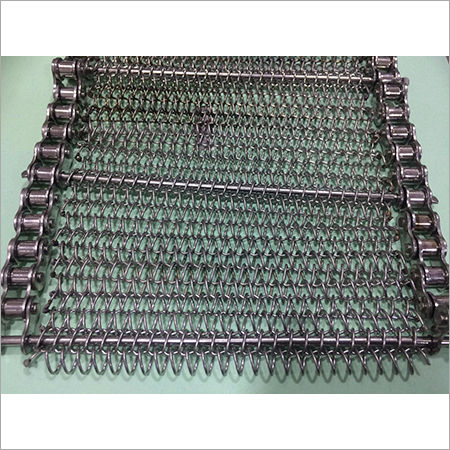

Balanced Mesh Conveyor Belt

40 INR/Piece

Product Details:

- Belt Type Balanced Mesh

- Power Source Mechanical (Driven by motorized rollers, if required)

- Thickness 310 mm

- Features High strength, Durable, Flexible, Easy Cleaning, Smooth Operation

- Surface Finish Polished, Electro-galvanized or Plain

- Material Stainless Steel, Carbon Steel, Galvanized Iron

- Type Balanced Mesh Conveyor Belt

- Click to View more

X

Balanced Mesh Conveyor Belt Price And Quantity

- 100 Square Foot

- 40 INR/Piece

Balanced Mesh Conveyor Belt Product Specifications

- Customizable; typically 0.11.5 m/s

- Industrial Ovens, Food Processing, Cooling, Baking, Freezing, Packaging

- Yes

- Not Required (Mechanical Conveyance)

- Corrosion Resistant, Heat Resistant

- Balanced Mesh

- Mechanical (Driven by motorized rollers, if required)

- Can be integrated

- Stainless Steel, Carbon Steel, Galvanized Iron

- Up to 1500 kg/m

- 310 mm

- Horizontal Mesh Structure

- Polished, Electro-galvanized or Plain

- Balanced Mesh Conveyor Belt

- High strength, Durable, Flexible, Easy Cleaning, Smooth Operation

Balanced Mesh Conveyor Belt Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

Balanced Mesh Conveyor Belt is one of the most versatile and hugely used conveyor belts that finds huge applicability industrial product processing, warehouses and various industries. It is left and right hand wire mesh that is joined/attached by crimped or connecting rod and is made up of excellent quality stainless steel. Provided conveyor belt is best known for excellent flexibility, strength to weight ratio, minimal or no maintenance, easy installation, flawless function and flat surface and is acclaimed for transporting a huge variety of products, especially small sized and which require a lot of support.

Versatile Design for Industrial Efficiency

Balanced Mesh Conveyor Belts are engineered to accommodate a wide variety of industrial requirements. They support high temperatures, adjustable mesh openings, and heavy load capacities, making them suitable for demanding applications such as food processing, heat treatment, and material handling. The customizable size and mesh flexibility allow seamless integration into existing conveyor systems, improving efficiency and productivity.

Durability and Strength You Can Trust

Constructed from premium materials including stainless steel, carbon steel, and galvanized iron, these conveyor belts are built to last. The robust mesh structure resists corrosion and heat, handling temperatures up to 1200C. Their tensile strength adapts to different wire diameters and materials, making them ideal for heavy-duty applications requiring reliability and low-maintenance operation.

Seamless Maintenance and Installation

Installation is straightforward with easy onsite fitting, and the belts design supports simple cleaning and inspection. Its smooth surface minimizes product contamination and makes regular maintenance hassle-free, saving time and resources. The belt is also mechanically driven, eliminating the need for electrical voltage and reducing operational costs.

FAQs of Balanced Mesh Conveyor Belt:

Q: How is the Balanced Mesh Conveyor Belt installed onsite?

A: The Balanced Mesh Conveyor Belt can be quickly and easily installed onsite, typically by attaching the belt to existing conveyor frameworks using appropriate mounting hardware. Detailed installation guidelines are provided to ensure hassle-free setup by maintenance teams.Q: What applications are suitable for the Balanced Mesh Conveyor Belt?

A: This conveyor belt is ideal for a range of industrial uses such as food processing, industrial ovens, baking, freezing, cooling, and packaging. Its adaptability also makes it valuable in sectors requiring heat and corrosion resistance, including manufacturing and material handling.Q: What are the benefits of the meshs adjustable opening and customizable width?

A: Adjustable mesh openings (2 mm to 50 mm) and width customization (100 mm to 4000 mm) enable tailored solutions for specific product or material sizes. This flexibility ensures optimal performance in various processes and easy integration with existing equipment.Q: Where can the Balanced Mesh Conveyor Belt be used within a production facility?

A: Due to its heat, corrosion, and load resistance, the belt can be utilized in diverse environments within a facility, such as processing areas, ovens, freezers, and packaging lines. It is suitable for both horizontal and inclined conveying systems and can be paired with roller conveyors.Q: What maintenance processes are recommended for this conveyor belt?

A: The belt is designed to be low-maintenance, requiring only periodic cleaning and visual inspections. Its construction allows residues to be easily removed, ensuring smooth operation and longevity without complex servicing.Q: How does the drive method work, and what are the speed options?

A: The conveyor belt operates via chain or friction-driven methods, typically using motorized rollers if needed. The speed can be customized to application needs, commonly ranging from 0.1 to 1.5 m/s, providing flexibility for varying production demands.Q: What advantages does using a Balanced Mesh Conveyor Belt provide over other belt types?

A: This belt offers high strength, flexibility, resistance to corrosion and heat, and simple cleaning, outpacing traditional belt types. Its mechanical operation removes voltage dependency, and its smooth structure aids easy product transfer, improving overall process efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Wire Mesh Conveyor Belts' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free