Food Grade Conveyor Belt

Product Details:

- Belt Type Flat Belt

- Surface Finish Smooth, Matt

- Power Source Electric

- Features Anti-static, Non-Toxic, Hygienic, Easy to Clean

- Thickness 2 mm to 10 mm

- Material PU, PVC, Rubber

- Type Food Grade Conveyor Belt

- Click to View more

Food Grade Conveyor Belt Price And Quantity

- 40 INR/Piece

- 100 Square Foot

Food Grade Conveyor Belt Product Specifications

- No

- Belt Conveyor

- Food Processing, Packaging, Pharmaceuticals, Bakery, Dairy

- Yes

- No

- 220-415 V

- 2 mm to 10 mm

- Anti-static, Non-Toxic, Hygienic, Easy to Clean

- PU, PVC, Rubber

- Oil Resistant, Heat Resistant, Fire Resistant

- No

- 1-5 m/s

- Food Grade Conveyor Belt

- Flat Belt

- 50-150 Kg per Meter

- Smooth, Matt

- 0.75 kW to 5.5 kW

- Electric

Food Grade Conveyor Belt Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

Food Grade Conveyor Belt is one of the most widely used conveyor belts in the food sector (tea, sugar industry) that is suitable for handling food items by directly moving food on the belt surface. We develop this type of conveyor belt using natural rubber that is suitable to transport reactive, acidic and non-oily materials. In addition to this, we also use special synthetic rubber that possess high moisture content and is suitable for oily as well as chemically active food items. Food packaging conveyor belt appears white in color and do not transfer color contamination or any odor to the food materials while handling. It is best characterized for preventing bacterial growth, providing uniform loads and safeguarding the possibility of water collection.

Product details of Food Grade Conveyor Belt

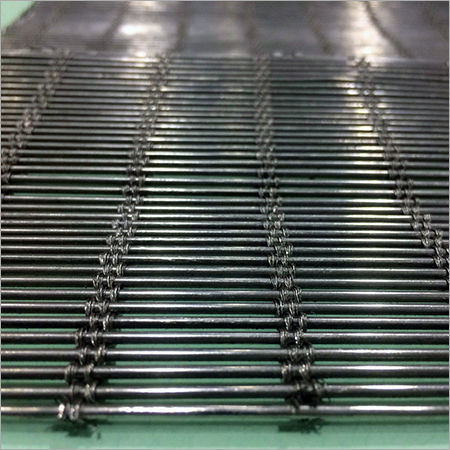

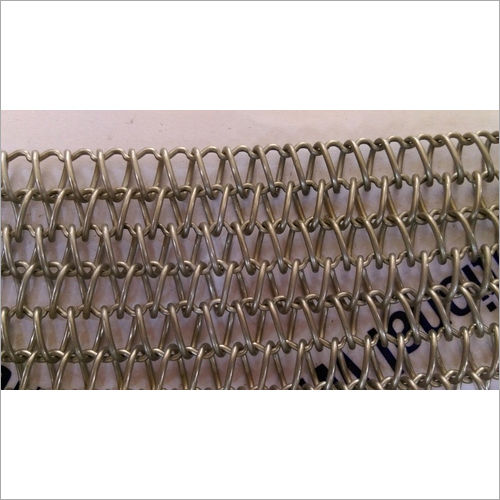

| Material | S.S |

| Wire Diameter | 1mm - 5 mm |

| Type of Belts | Balanced Belts, Double Balanced belts, Gratex Belts, Duplex Belts, Compound Balanced Belts |

| Grade | AISI 304/316 |

| Form | Flat weave, load bearing, flexible |

| Material Type | Wire or metal strap |

Tailored for Every Need

Designed for maximum versatility, our food grade conveyor belts can be customized in thickness, width, and length to suit the specific demands of your facility. Whether you require a moulded or cut edge or optional cleats for product movement, we provide solutions tailored to your production lines, ensuring smooth and safe material transfer.

Certified Safety and Compliance

Our belts are FDA-approved and made from non-toxic, anti-static materials that are easy to clean and maintain. Engineered for use in highly regulated industries, they guarantee the highest standards in hygiene and compliance, supporting a safe environment for food and pharmaceutical products.

Performance Under Pressure

With a load capacity of 50150 kg per meter and heat, oil, and fire resistance, these conveyor belts thrive in challenging settings. Designed for steady speeds (15 m/s) and consistent performance across varying power ranges (0.75 kW to 5.5 kW), they are reliable in continuous, high-throughput processing.

FAQs of Food Grade Conveyor Belt:

Q: How is the Food Grade Conveyor Belt installed and joined?

A: The conveyor belt can be installed using endless looping, mechanical fasteners, or vulcanized splicing, ensuring a secure and seamless connection for reliable operation. The installation method depends on your specific process and facility requirements.Q: What environments and temperatures can the conveyor belt withstand?

A: Designed for versatility, these belts operate efficiently in temperatures ranging from -10C to +80C. They are resistant to oils, heat, and fire, making them ideal for diverse settings such as bakeries, dairies, and food processing plants.Q: When should I choose belts with cleats or a specific edge finish?

A: Opt for belts with optional cleats when you need to prevent product slippage or handle inclined transport. Choose moulded edges for enhanced durability, or cut edges for adaptability, based on the demands of your production process.Q: Where are Food Grade Conveyor Belts typically used?

A: These belts are widely used in food processing, packaging, pharmaceuticals, bakeries, and dairy plants. Their hygienic, non-toxic construction ensures safe handling of edible or sensitive products in compliance with industry regulations.Q: What are the main benefits of using FDA-approved, food grade belts?

A: FDA approval assures that the belts are non-toxic, hygienic, and suitable for direct contact with food products. Their easy-to-clean design minimizes contamination risks, supporting safe and efficient operations in regulated industries.Q: How do I determine the right belt type and dimensions for my needs?

A: Consult with our technical team or supplier to specify your requirements regarding length (customizable), width (up to 3000 mm), thickness (210 mm), and load capacity. This ensures optimal performance tailored to your application.Q: What maintenance is required for these conveyor belts?

A: Regular cleaning and inspection are recommended, thanks to their smooth, easy-to-clean surface. This helps sustain hygienic standards and prolong belt lifespan, especially in environments with strict sanitary requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Wire Mesh Conveyor Belts' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS