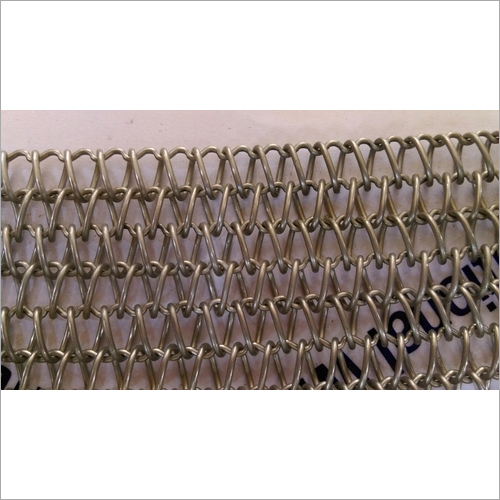

Balanced Weave Belt

40 INR/Piece

Product Details:

- Belt Type Balanced Weave Belt

- Features Even mesh, Durable, Easy to clean, Good tracking, High strength

- Thickness 2 mm to 10 mm (customizable)

- Power Source None/Manual/Mechanical

- Surface Finish Polished/Smooth

- Material Stainless Steel, Mild Steel, High Carbon Steel

- Type Wire Mesh Conveyor Belt

- Click to View more

X

Balanced Weave Belt Price And Quantity

- 100 Square Foot

- 40 INR/Piece

Balanced Weave Belt Product Specifications

- Polished/Smooth

- Yes

- 2 mm to 10 mm (customizable)

- Corrosion Resistant, Heat Resistant

- Wire Mesh Conveyor Belt

- None/Manual/Mechanical

- No

- Even mesh, Durable, Easy to clean, Good tracking, High strength

- Stainless Steel, Mild Steel, High Carbon Steel

- Mesh Belt, Stainless Steel

- Up to 30 m/min (customizable)

- Customizable as per requirement

- Manual/Mechanical

- Balanced Weave Belt

Balanced Weave Belt Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

Leveraging on our years of experience, we have been able to manufacture and export a premium range of balanced weave belt. We are manufacturing our products using best quality of stainless steel and equipments. These products are highly demanded in the global market owing to their high strength and durability features. The offered range of products is available in different sizes and grades to our customers. Balanced weave belt finds their applications in varied industries like food processing, glass, ceramic and metal works.

Further Details of Balanced Weave Belt :

| Type L/K-19, 24-10, 20-10 | |

| Specification | 24-10, 20-10 24 coils of 10 swg per foot width. 20 crimpled cross members of 10 swg per foot length |

| Details | Weight: 22 kg per sq. mt. Thickness: 9 - 10 mm Maximum working tension -270 lbs per foot width of the belt |

| Application | A general purpose balanced weave conveyor belt. Specially suitable for glass annealing Lehrs. |

Superior Material Choice

Crafted from premium stainless steel, mild steel, or high carbon steel, our balanced weave belts withstand high temperatures and resist corrosion. With a smooth, polished finish, they maintain cleanliness and structural integrity, even in rigorous operating environments.

Tailored to Your Needs

We offer full customization for belt thickness, width, load capacity, and speed (up to 30 m/min), meeting the unique requirements of your operation. Whether you need a specific mesh size or custom build, we work closely with you to deliver a perfect fit every time.

Engineered for Reliability

The even mesh design of our balanced weave belts ensures superb tracking and consistent product handling. Their durable construction guarantees longevity under continuous use, making them ideal for diverse manufacturing and processing industries.

FAQs of Balanced Weave Belt:

Q: How is a balanced weave belt used in industrial processes?

A: A balanced weave belt is commonly used to convey products through ovens, furnaces, coolers, or washers, thanks to its durability, heat resistance, and even mesh structure that ensures smooth product movement and reliable tracking.Q: What materials are available for this wire mesh conveyor belt?

A: Our balanced weave belts can be manufactured from stainless steel, mild steel, or high carbon steel, allowing you to choose the best option for your applications requirements, such as resistance to corrosion or high temperatures.Q: When should a business consider customizing the load capacity or speed of the belt?

A: Customization is recommended whenever your operational needs require specific throughput rates or when handling heavier loads to optimize both safety and performance. We can tailor the belts load capacity and speed up to 30 m/min accordingly.Q: Where are balanced weave belts most beneficially applied?

A: These belts excel in industries such as food processing, glass manufacturing, metal treatment, and automotive, especially where heat resistance, cleanliness, and durability are critical.Q: What is the process for ordering a customized balanced weave belt?

A: Simply provide your specificationsincluding material preference, dimensions, required load capacity, speed, and surface finish. Our team will design and manufacture a belt tailored to your needs, with consultation throughout the process.Q: How does the polished/smooth finish of the belt benefit users?

A: A polished or smooth surface finish enhances cleanliness, prevents product contamination, and allows for easier belt cleaning between uses, supporting stringent hygiene and quality control standards.Q: What are the key benefits of using this balanced weave conveyor belt?

A: Key benefits include exceptional strength, reliable tracking, easy maintenance, resistance to heat and corrosion, and the versatility offered by customizable options, making them suitable for a wide array of industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Wire Mesh Conveyor Belts' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS