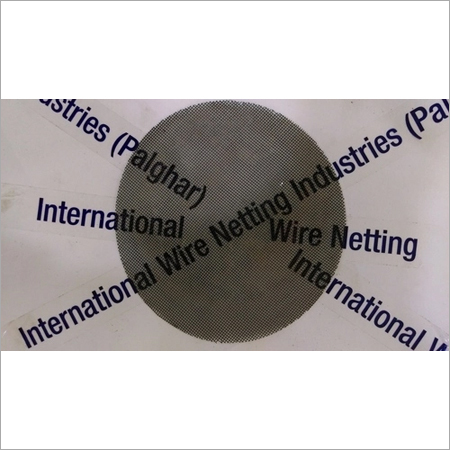

Circular Vibrating Screen Mesh

40 INR/Piece

Product Details:

- Type Vibrating Screen Mesh

- Material Spring Steel / Stainless Steel

- Processing Type Woven

- Condition New

- Shape Circular

- Layer Single / Multi Layer

- Dimension (L*W*H) Customized

- Click to View more

X

Circular Vibrating Screen Mesh Price And Quantity

- 100 Square Foot

- 40 INR/Piece

Circular Vibrating Screen Mesh Product Specifications

- Woven

- Spring Steel / Stainless Steel

- Customized

- Low

- Electric

- Wire Mesh

- New

- Circular

- Vibrating Screen Mesh

- Single / Multi Layer

- 50/60 Hz

- Screening & Separation

Circular Vibrating Screen Mesh Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

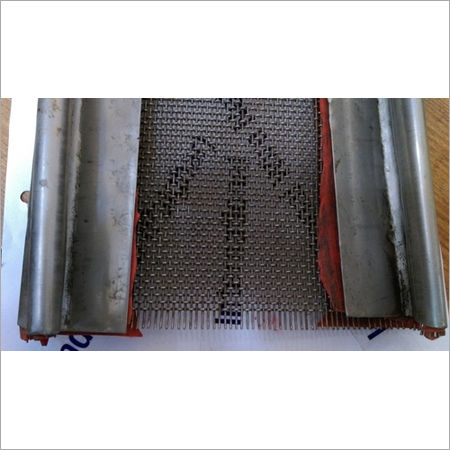

Our organization is manufacturing and exporting a wide array of Circular Vibrating Screen Mesh. These products are manufactured using upgraded quality raw material which is sourced from the reliable vendors. The offered range of vibrating screen is widely used in construction, agriculture and poultry industries for screening of all fibers containing impurities. Circular vibrating metal screen mesh are available in different sizes, lengths and specifications as demanded by our patrons. Our customers can avail these vibrating screens at reasonable prices.

Precision Screening & Separation

Achieve superior material handling with our circular vibrating screen mesh, engineered for high-efficiency screening and separation. Its woven wire mesh design, together with low-noise operation, ensures dependable performance in demanding industrial environments. Fit for multiple sectors, it accommodates both single and multi-layer arrangements to match unique workflow requirements.

Robust Build and Customization

Each mesh is crafted from high-quality spring steel or stainless steel for enhanced durability and resistance to wear. Customization options in dimensions and layer design guarantee compatibility with a wide range of equipment and processes. This flexibility makes the mesh ideal for partners seeking tailored solutions.

FAQs of Circular Vibrating Screen Mesh:

Q: How does the circular vibrating screen mesh improve screening efficiency?

A: The circular vibrating screen mesh enhances screening efficiency by utilizing a woven wire structure that promotes effective separation of materials while operating on electric power at low noise levels. Its vibration mechanism ensures rapid and uniform distribution of material across the mesh.Q: What materials are used in the construction of the vibrating screen mesh?

A: Our vibrating screen mesh is constructed from premium spring steel or stainless steel, making it durable, resistant to corrosion, and suitable for demanding industrial operations.Q: When should I choose a single layer versus a multi-layer configuration?

A: A single-layer configuration is ideal for straightforward screening needs, while multi-layer setups are recommended for separating materials into different sizes or for more complex processing tasks.Q: Where can the circular vibrating screen mesh be applied?

A: This product is widely used in industries requiring screening and separation, such as mining, aggregates, pharmaceuticals, food processing, and recycling. Its customizable dimensions allow integration into existing systems.Q: What is the process for ordering customized screen mesh dimensions?

A: To order a mesh with customized dimensions, provide your specific requirements (length, width, height, number of layers) during your inquiry. Our team will assist you through every step, from consultation to manufacturing and delivery.Q: How does this vibrating screen mesh benefit industrial operations?

A: By offering precise separation capabilities, low noise operation, and robust, customizable designs, our mesh increases productivity, reduces maintenance downtime, and supports consistent material quality across any application.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Vibrating Screen Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free