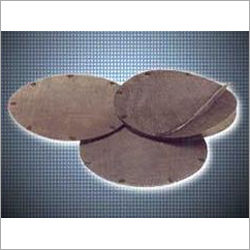

Multilayer Cylindrical Screen

40 INR/Piece

Product Details:

- Type Multilayer Cylindrical Screen

- Material Stainless Steel (304/316), Mild Steel

- Processing Type Welded/Perforated/Woven

- Condition New

- Shape Cylindrical

- Capacity Custom as per requirement

- Diameter Custom (e.g. 100 mm to 1200 mm or as specified)

- Click to View more

X

Multilayer Cylindrical Screen Price And Quantity

- 100 Square Foot

- 40 INR/Piece

Multilayer Cylindrical Screen Product Specifications

- Manual/Automatic

- Water Treatment, Pulp & Paper, Food Processing, Chemical Industry, Oil Filtration, Mining

- Low (if motorized)

- Liquid/Solid Filtration

- 110-380 V (if motorized)

- Custom as per requirement

- 2-5 layers or customized

- Welded/Perforated/Woven

- New

- Custom as per order

- Polished/Customized

- Cylindrical

- Custom (e.g. 100 mm to 1200 mm or as specified)

- 50-60 Hz

- Stainless Steel (304/316), Mild Steel

- Multilayer Cylindrical Screen

- Low

Multilayer Cylindrical Screen Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

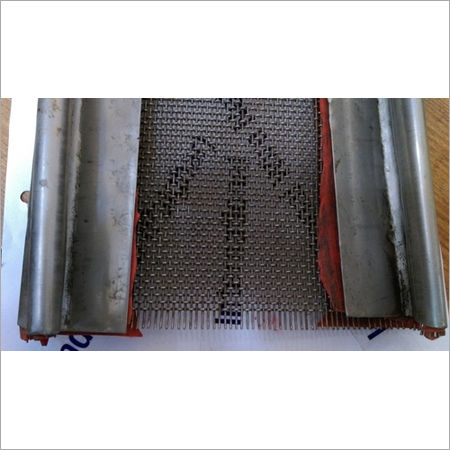

Multilayer Cylindrical Screen are also known as candle filters, where this screen is used as a multilayer film at lamination plants that has edges welded in a manner that offers long lasting strength. They are gathered in proper lapping to eliminate operator error on being used. The greatest benefit of this wired mesh is that it can be cleaned easily and is reusable in nature. The wires in the screen have been coated with material that imparts corrosion resistance and prevents from reacting with acids. Due to its resistance to thermal expansion, it is extensively used in electrical and automobile industries. This Multilayer Cylindrical Screen can be availed for various other lamination & multilayer film plants as per the required dimensions.

Key Features ofMultilayer Cylindrical Screen

- Durable plastic coating on the wires for protection against water and air

- Made from superior quality of stainless steel or carbon steel

- Diameter: 1-40 inch (20-1000 mm)

- Longer service life

Product details

|

Layers |

from 1 to 8 layers |

|

Shape |

Cylindrical |

|

Weave Style |

Plain Weave, Twilled, Dutch |

|

Usage |

Industrial |

|

Material |

Stainless steel |

|

Diameter |

1-40 inch (20-1000 mm) |

|

Material Grade |

AISI 304,316 |

High Precision and Durability

Each multilayer cylindrical screen is constructed with precision-welded, perforated, or woven layers, delivering superior strength and reliable filtration down to 10 microns. The polished or customized surface finish resists contamination and corrosion, making it ideal for long-term operation in harsh environments. High-grade materials reinforce durability even under rigorous cleaning and repeated use.

Flexible Customization and Connectivity

With customizable diameter, length, and number of layers, our screens can be tailored for specific capacity and application needs. They feature versatile end connectionschoose from flanged, threaded, or plainto facilitate easy installation across existing or new systems. Both metallic silver and tailored color finishes are available for optimal compatibility with your process line.

Efficiency, Low Maintenance, and Clean Operation

Operating at a low noise level, our cylindrical screens suit environments sensitive to sound disturbances. They support both manual and automatic, motorized modes at low power consumption, fitting into 110-380 V and 50-60 Hz setups. Cleaning is simplified through backwash mechanisms or manual processes, ensuring minimal downtime and sustained filtration performance.

FAQs of Multilayer Cylindrical Screen:

Q: How is the multilayer cylindrical screen cleaned and maintained?

A: The multilayer cylindrical screen can be cleaned using either a backwash system or manual procedures. Regular cleaning depends on the filtered medias load and application demands, ensuring reliable performance and extended service life. Maintenance involves periodic inspection and washing to prevent clogging and to restore original filtration precision.Q: What materials are used in the construction of these screens?

A: Our screens are crafted from high-grade stainless steel (304/316) or mild steel, offering excellent mechanical strength, corrosion resistance, and durability for demanding filtration tasks. The polished or custom coatings further enhance cleanliness and longevity, making them suitable for a range of industrial applications.Q: When should I use a flanged, threaded, or plain end connection?

A: Flanged connections are ideal for heavy-duty or high-pressure systems, ensuring secure installation. Threaded ends simplify integration when quick assembly or disassembly is needed. Plain ends are suitable where welded or adhesive sealing is preferred. The selection largely depends on your systems assembly requirements and pressure specifications.Q: Where can multilayer cylindrical screens be applied?

A: These screens are extensively utilized in water treatment plants, chemical industries, pulp & paper mills, food processing facilities, mining operations, and oil filtration setups. Their customizable design and corrosion-resistant properties make them adaptable for various liquid or solid filtration needs.Q: What is the typical process flow when using this screen for filtration?

A: Liquids or solids enter the cylindrical screen through one end, flow across multiple mesh layers, and contaminants are trapped as clean media exits. The high-precision mesh layers ensure targeted particle removal, while the multilayer arrangement prevents rapid clogging and allows for efficient filtration with minimal flow disruption.Q: What benefits does a multilayer design offer over single-layer screens?

A: A multilayer screen provides enhanced filtration efficiency, increased dirt-holding capacity, and longer operational intervals between cleanings. The arrangement also minimizes pressure drop and deformations, improving lifespan and reducing maintenance frequency, especially under challenging operational conditions.Q: Is OEM customization available for unique applications or industry standards?

A: Yes, we offer OEM services for screens with specific diameters, pressure ratings, mesh sizes, coatings, colors, and power requirements. This ensures precise compatibility and seamless integration into your industrial processes, meeting the exact technical standards you require.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Vibrating Screen Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free