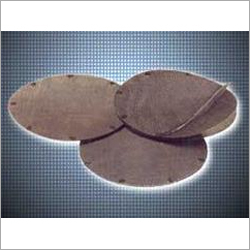

Multilayer Circular Screen

Product Details:

- Type Vibratory Circular Screen

- Material Stainless Steel, Mild Steel

- Processing Type Welded, Assembled

- Condition New

- Shape Circular

- Capacity 100 kg to 2 tons/hour

- Diameter 600 mm to 1800 mm

- Click to View more

Multilayer Circular Screen Price And Quantity

- 40 INR/Piece

- 100 Square Foot

Multilayer Circular Screen Product Specifications

- Vibratory Circular Screen

- Screening, Separation, Grading

- 600 mm to 1800 mm

- Welded, Assembled

- Low

- 2-5 layers

- 220-240 V

- Mild Steel / SS304 / SS316

- As per model

- New

- Granular, Powder, Liquid

- Stainless Steel, Mild Steel

- Circular

- Electric

- 100 kg to 2 tons/hour

- 2-5 kW

- 50/60 Hz

Multilayer Circular Screen Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

Multilayer Circular Screen is made from superior quality of rust proof metals and alloys that makes a finely knitted mesh in circular structure. This screen can be fitted over vents and openings to offer protection from contamination from any foreign particle from outside. It is very helpful in industries where a molten mass needs to be processed without getting mixed with impurities in the extrusion process. It has a metallic framing around the edges to provide the strength and durability that is required by this screen to last longer and fit well. Further, this Multilayer Circular Screen is available in any size and combination of meshes as per your requirements.

Key Features ofMultilayer Circular Screen

- Can be assembled in packs to eliminate operator error

- Very strong, sturdy and ideal for problem free filtering

- High durability along with physical as well as chemical resistance

- Largely used at pet recycling, BOPP film plants, and non-woven fabric plants

Product details

|

Filter Disc Shape |

Circular |

|

Length |

0 -5 inch, 5-10 inch, 10-15 inch, 15-20 inch |

|

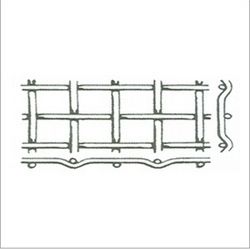

Weave Style |

Plain Weave, Twilled, Dutch |

|

Usage |

Industrial |

|

Material |

Stainless Steel Wire |

|

Type |

Expanded Wire Mesh |

|

Wire Diameter |

0.01- 1.2 mm, 0.025- 2.5 m |

Versatile Screening Solution for Industrial Needs

Our Multilayer Circular Screen delivers high-efficiency screening, separation, and grading for a wide variety of materials. With options for both semi-automatic and automatic operation, as well as customized mesh sizes and multiple layers, this equipment is engineered to adapt to your production requirements. Designed for reliability, low noise, and simple operation, it is ideal for food, chemical, pharmaceutical, and minerals industries.

Customizable Design for Maximum Productivity

Choose from multiple coating types, screen diameters, mesh sizes, and discharge outlets to tailor the machine to your specific needs. The system supports input via a top inlet and offers easy model-specific dimensioning. This flexibility ensures maximum throughput with a range of capacities and efficient separation in every batch processed.

FAQs of Multilayer Circular Screen:

Q: How does the Multilayer Circular Screen operate for screening and separation?

A: The Multilayer Circular Screen works using an unbalanced motor that generates vibratory motion, causing the material to move across the screen surface. The material is fed through the top inlet and separated into different grades as it passes through mesh layers ranging from 20 to 500 mesh. Multiple discharge outlets ensure efficient sorting according to particle size.Q: What materials can be processed using this circular screening machine?

A: This machine is suitable for granular, powder, and liquid materials, making it versatile for screening, separation, and grading in various industries such as chemicals, pharmaceuticals, food processing, minerals, and more.Q: Where is the Multilayer Circular Screen commonly installed and used?

A: The device is designed for floor-mounted installation in industrial processing plants and manufacturing facilities across India and globally. It is favored by distributors, exporters, manufacturers, and suppliers for its robust performance and flexibility.Q: What are the benefits of having multiple discharge outlets and screen layers?

A: Multiple discharge outlets allow simultaneous separation of materials into different grades, improving process efficiency. The 2 to 5 customizable screen layers enable precise grading or classification in a single operation, enhancing productivity and reducing processing times.Q: How is the mesh size customized for specific screening requirements?

A: Mesh size can be selected anywhere from 20 mesh to 500 mesh based on the applications need. The supplier will configure the screen according to the target particle size or separation grade, ensuring optimal performance for every process.Q: When should I consider using the automatic or semi-automatic options?

A: Automatic models with a control panel and variable frequency drive are best for continuous, large-scale operations needing less manual intervention. Semi-automatic versions suit smaller batches or applications where operator control is necessary.Q: What safety and maintenance features are included in the design?

A: The machine features polished surfaces for easy cleaning, robust welded and assembled construction, and optional mobility with castor wheels. It runs on electric power with low noise output and operates safely up to 80C, ensuring durability and consistent performance with minimal maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Vibrating Screen Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free