Compound Balanced Weave Belt

40 INR/Piece

Product Details:

- Surface Finish Smooth, Metallic

- Belt Type Compound Balanced Weave

- Power Source Mechanical

- Material Stainless Steel, Mild Steel, Galvanized Iron

- Type Compound Balanced Weave Belt

- Structure Metal Wire Mesh Construction

- Belt Conveyor Compatible

- Click to View more

X

Compound Balanced Weave Belt Price And Quantity

- 40 INR/Piece

- 100 Square Foot

Compound Balanced Weave Belt Product Specifications

- Compound Balanced Weave Belt

- Mechanical

- Compound Balanced Weave

- Compatible

- Smooth, Metallic

- Stainless Steel, Mild Steel, Galvanized Iron

- Metal Wire Mesh Construction

- Food Processing, Baking, Freezing, Annealing, Heat Treatment, Industrial Conveying

- Variable, depends on application

- Compatible

- Heat Resistant, Corrosion Resistant

- Customized as per requirement

Compound Balanced Weave Belt Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

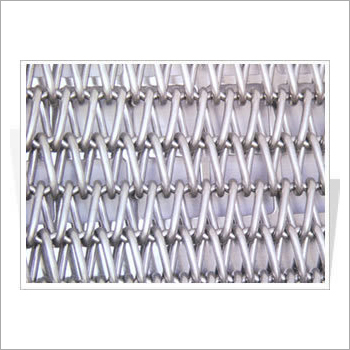

We are the leading manufacturer and exporter of Compound Balanced Weave. These products are manufactured under the guidance of expert professionals. We supply our weave using topmost quality material which is sourced from the trusted vendors of the society. Our range is manufactured in compliance with industry standards and norms. Offered range of balanced weave is available in different technical specifications to our esteemed customers. Compound Balanced Weaves are available in the market at affordable prices.

Further Details of Compound Balanced Weave Belt

| Type L/K-5, 60-16, 40-16 | |

| Specification | 60-16, 40-16 60 coils of 16 swg per foot width 40 crimped cross members of 15 swg per foot length |

| Details | Weight: 12.5 kg per sq. mt. Thickness: 8 mm Maximum working tension - 1150 lbs per foot width |

| Application | All purpose balanced weave belt specially used for I.S. Machine conveyors in Glass Industry |

| Note | Available in 60-20, 40-18, 60-18, 40-16 |

Robust Metal Mesh Construction

Built with a compound balanced weave structure, this belt offers outstanding strength and dimensional stability. The intricate metallic mesh delivers smooth product movement while resisting distortion under high loads and variable speeds. The design enhances operational safety and optimizes throughput, making it suitable for rigorous industrial applications.

Tailored for Diverse Industrial Needs

Choose from stainless steel, mild steel, or galvanized iron to meet specific process requirements. Every belt is customized in load capacity and dimensions to adapt perfectly to your conveyor systems. The smooth and hygienic surface is particularly advantageous in food-grade and high-temperature environments, ensuring compliance and reliability.

FAQs of Compound Balanced Weave Belt:

Q: How is the load capacity of the Compound Balanced Weave Belt determined?

A: The load capacity of the Compound Balanced Weave Belt is customized according to your specific application needs and conveyor requirements. Our engineering team collaborates with you to determine the optimal configuration for your load, ensuring safe and efficient operation.Q: What advantages does the Compound Balanced Weave Belt offer in heat and corrosion-prone environments?

A: This belt is manufactured from premium stainless steel, mild steel, or galvanized iron, providing excellent resistance against heat and corrosion. Such features make it ideal for applications in baking, industrial heat treatment, and environments where chemical or moisture exposure occurs.Q: Where can the Compound Balanced Weave Belt be installed?

A: The belt is versatile for installation on both belt and roller conveyor systems. It is compatible with various setups used in food processing plants, industrial ovens, freezing systems, annealing lines, and general material handling facilities.Q: What processes benefit from using this metal wire mesh belt?

A: Processes like food baking, freezing, annealing, heat treatment, and other industrial conveying operations greatly benefit from the belts smooth metallic surface and temperature resilience. This ensures product integrity and hygienic transport in challenging environments.Q: How does the metallic surface finish enhance belt performance?

A: A smooth metallic surface finish minimizes product sticking, eases cleaning, and improves hygiene. It also reduces friction between the belt and your products, promoting efficient movement and preserving product quality during conveying.Q: What are the usage and application areas for this conveyor belt?

A: The belt is ideal for usage in the food processing industry, industrial baking, freezing tunnels, annealing processes, heat treatment facilities, and general industrial conveying applications where mechanical reliability and material hygiene matter most.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Wire Mesh Conveyor Belts' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free