Steel Vibrating Screen Mesh

40 INR/Piece

Product Details:

- Type Vibrating Screen Mesh

- Material High Carbon Steel, Stainless Steel, Mild Steel

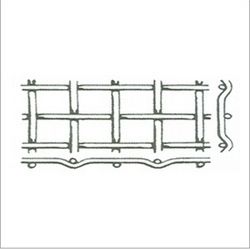

- Processing Type Woven Mesh

- Condition New

- Shape Rectangular or Square

- Diameter Wire diameter: 1.5 mm 12 mm

- Dimension (L*W*H) Customizable as per client requirement

- Click to View more

X

Steel Vibrating Screen Mesh Price And Quantity

- 100 Square Foot

- 40 INR/Piece

Steel Vibrating Screen Mesh Product Specifications

- Wire diameter: 1.5 mm 12 mm

- Customizable as per client requirement

- Vibrating Screens, Stone Crusher Plants, Mining, Quarrying, Construction

- New

- Manual

- Rectangular or Square

- Silent Operation

- High Carbon Steel, Stainless Steel, Mild Steel

- Woven Mesh

- Vibrating Screen Mesh

- Steel

Steel Vibrating Screen Mesh Trade Information

- 1000 Square Foot Per Week

- 2-7 Days

Product Description

In order to fulfil the changing demands of our clients, we are engaged in manufacturing and exporting a premium range of Steel Vibrating Screen Mesh. All these products are manufactured using topmost quality raw material which is sourced from the trusted vendors. The offered range of screen is mostly used in cement, sugar, paper, coal and mining industries. These Vibratory Screen Mesh are very light in weight and easy to handle. Our patrons can avail these products at moderate prices from the market.

Features:

- The screens are designed to bear heavy loads

- Highly resistant to vibrations and shocks

- These are highly damage resistant

- Coated for long term protection against corrosion

- Durable in quality, these screens have excellent dimensional tolerance

- Stringently tested for their finishing and strength

- Acclaimed among clients for their excellent abrasion resistance

The excellent quality Vibrating Screen Mesh offered by our company International Wirenetting Industries, are specially designed to meet with exceptionally sturdy operating conditions like processing of heavy abrasive materials like sand, non- metallic and metallic materials, crushed stones, oreos, coal slag and many more.

In a wide assortment of sizes our Vibrating Screen Mesh are available so that the demands of a wide clientele can be met. It generally finds their application in construction and chemical industry for sand, sizing stones, ores and gravel and ores materials due to their non reactivity towards alkalis and acids. We can also meet with the bulk orders demands on time.

In a wide assortment of sizes our Vibrating Screen Mesh are available so that the demands of a wide clientele can be met. It generally finds their application in construction and chemical industry for sand, sizing stones, ores and gravel and ores materials due to their non reactivity towards alkalis and acids. We can also meet with the bulk orders demands on time.

Specifications:

- Material: Stainless steel

- Size: As per customer specifications

We manufacture the screens from different types of materials like mild steel, stainless steel, spring steel, GI wires to suite all kinds of applications. Our Vibrating Screen Mesh are woven with precision into any diameter wire or rod to meet customers specific requirements.

Product details

| Material Grade | 304 or 316 |

| Material | Stainless Steel |

| Hole Shape | Rectangular |

| Surface Finishing | Galvanized |

| Application | Mineral Separation, Coal Mine, Building Material, Abrasive Industry, Chemical Industry |

| No of Mesh | 100 |

Custom Engineered for Diverse Applications

Our Steel Vibrating Screen Meshes are tailored to meet rigorous demands in mining, stone crushing, quarrying, and construction. With customizable dimensions and a selection of steel grades, each mesh delivers optimal results in screening operations. The versatility of shape and size, combined with silent operation, ensures exceptional performance and longevity.

Superior Strength and Durability

Manufactured using advanced weaving processes, these meshes offer maximum strength and resistance to wear. High carbon steel, stainless steel, and mild steel provide corrosion and abrasion resistance, making the product ideal for heavy-duty usage. Each mesh is meticulously tested and supplied in new condition to guarantee reliability.

FAQs of Steel Vibrating Screen Mesh:

Q: How is the steel vibrating screen mesh used in stone crusher plants and mining?

A: The steel vibrating screen mesh is installed in vibrating screens within stone crusher plants and mining operations. It efficiently separates different sizes of material, ensuring optimal processing and grading for further use or disposal.Q: What materials are available for the vibrating screen mesh?

A: The vibrating screen mesh is available in high carbon steel, stainless steel, and mild steel options, enabling selection based on required strength, corrosion resistance, and application conditions.Q: When should I choose woven mesh over other types for my operations?

A: Woven mesh is ideal when demanding heavy-duty screening processes with durability and flexibility are necessary. It is best used in environments where mesh needs frequent replacement or must endure abrasive materials.Q: Where can the steel vibrating screen mesh be applied apart from mining and quarrying?

A: Beyond mining and quarrying, these meshes are extensively used in stone crusher plants and construction sites, where accurate separation of materials is crucial for productivity and efficiency.Q: What is the process for customizing dimensions of the mesh?

A: To customize the dimensions, clients can specify desired length, width, and wire diameter. The manufacturer then weaves the mesh to these specifications, ensuring a precise fit for each application.Q: How does the silent manual power mode benefit operations?

A: Silent manual power mode ensures low noise levels during operation, contributing to a safer and more comfortable working environment. It also enhances operational control without excessive mechanical or electrical dependence.Q: What benefits does the steel vibrating screen mesh offer to distributors and exporters in India?

A: Distributors and exporters benefit from a versatile, high-quality product that can be tailored to various requirements. Its durability, silent operation, and adaptability make it a preferred choice for clients, expanding market reach and reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Vibrating Screen Mesh' category

|

INTERNATIONAL WIRENETTING INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS